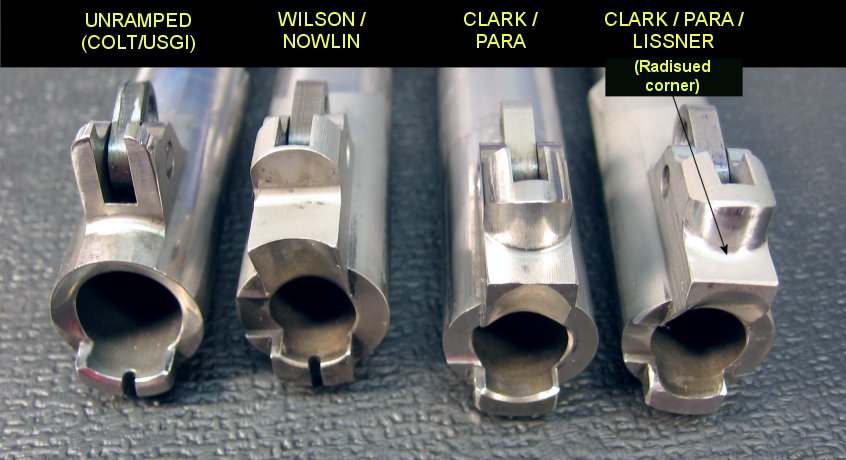

Ramped Barrels - Styles

Cutting Frames For Ramped Barrels

Instructions Courtesy of Schuemann Barrels

Clamp the frame in a mill vise with the frame rails horizontal. Install an 11/32 inch

or smaller flat bottom end mill. Set the machine zero at the top of the rails, then move the

end mill downward 0.315 inch and cut a slot aft from the standing lug slot to the magazine

well, centered between the rails. For best accuracy, the slot should form a tight slip fit with

the barrel standing lugs.

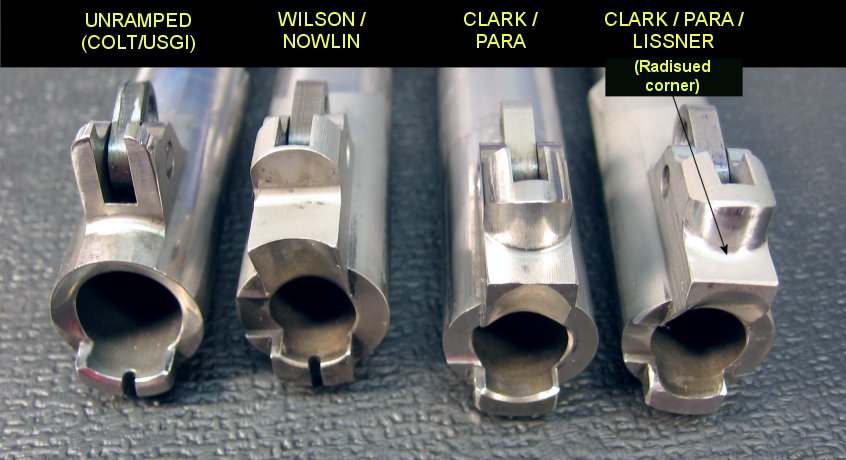

(Wilson/Nowlin Ramped Barrels Only) Insert a slide stop into the frame.

Measure the distance between the rear of the slide stop pin and the aft face of the standing lug slot. Subtract this distance from 0.500. Clamp the frame in the mill vise with the

frame rails vertical, and using a 29/64 inch flat bottom end mill or the Nowlin ramped barrel frame bridge cutter, move the aft face of the frame standing lug slot downward (aft relative to the frame) by the resultant distance (typically about 0.160). Then clamp the frame

in the mill vise with the frame rails at 45 degrees from vertical. Chamfer the corner at the

intersection of the two above cuts. The intersection is chamfered its full length between

the sides of the frame standing lug slot and the chamfer has a width of 0.050 inch. Using

a flat needle file, round the two edges of the chamfer to match the rounded mating corner

on the barrel (1/16” radius).

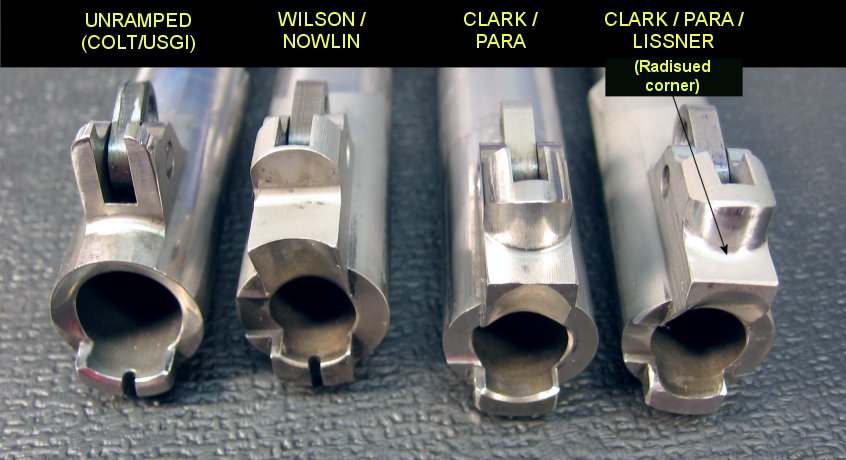

(Clark/ParaOrdnance Ramped Barrels Only) Insert a slide stop into the frame.

Measure the distance between the rear of the slide stop pin and the aft face of the standing lug slot. Subtract this distance from 0.600. Clamp the frame in the mill vise with the

frame rails horizontal, and using a 3/8 inch flat bottom end mill do a vertical plunge cut,

moving the aft face of the frame standing lug slot aft by the resultant distance (typically

about 0.260), with the end mill centered between the rails. Use a Dremel tool to round the

corner at the top of the cut to a 1/16” radius to match the fillet on the barrel standing lugs.